software calculation Design: propeller turbine, screw, aerial, marine, turbine, tidal, wind, kaplan, foil, wings, 3D. Discover heliciel software:

propeller propulsion or turbine building: function "re-build" and performances "offdesign"

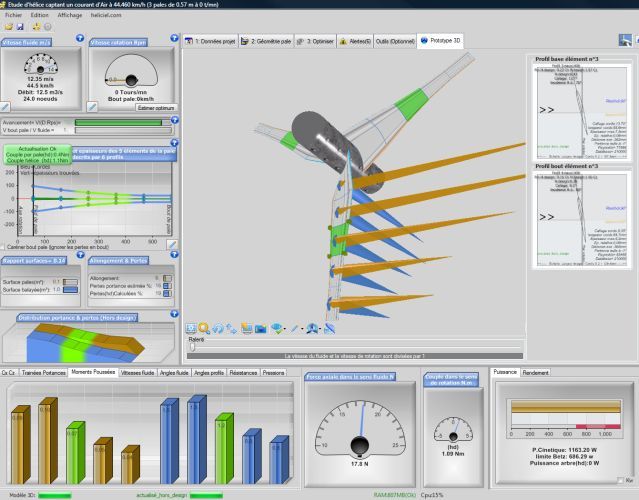

Understand and master the propeller design with the simulation 3D software Heliciel:

Re build:

for example by modifying the length of the blade, to ensure that the twisting of the blades, the 3D model, and performance of thrust and torque are updated according to the operating point , and the new geometry of the propeller, you must rebuild the propeller, click (rebuild) propeller in the tool bar::

How heliciel built propeller?

2 propeller construction methods are possible:

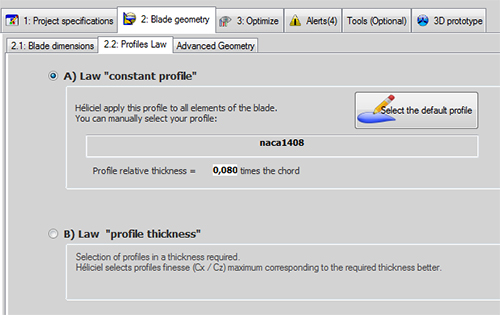

- Build a propeller blade profiles constant. (default law, recommended at the beginning.)

If you selected the law of constant profile (default law, recommended at the beginning), the thicknesses of the blade will be proportional to the widths of the elements of the blade. This implies that even if the width of the blade varies between the foot and the blade tip, the shape of the profile is constant. When you click on re build the propeller:

, Heliciel select from the database, of the constant profile, imposed on the entire blade, the angle of incidence providing the best lift / drag ratio. Data Cd and CL are used to solve the system of equations of the induced velocities, by the method of blade elements and the change of momentum(BEM), taking into account the correction of the blade tip losses resulting from the vortex theory. When the induced velocities are resolved Heliciel calculating the performance, torque and thrusts on each blade elements, and derives the overall result for the propeller.Twisting of the blade is made so that the angles of incidence reflect induction.

, Heliciel select from the database, of the constant profile, imposed on the entire blade, the angle of incidence providing the best lift / drag ratio. Data Cd and CL are used to solve the system of equations of the induced velocities, by the method of blade elements and the change of momentum(BEM), taking into account the correction of the blade tip losses resulting from the vortex theory. When the induced velocities are resolved Heliciel calculating the performance, torque and thrusts on each blade elements, and derives the overall result for the propeller.Twisting of the blade is made so that the angles of incidence reflect induction. - Build a propeller with a thickness distribution changing the shape of the profiles. (More complex to use when mastering the default method.)

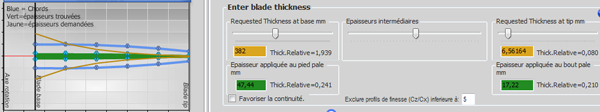

If you selected the law thickness profile, you can use the slider thicknesses of blade, If you selected the law thickness profile, you can use the slider thicknesses of blade (= chords profiles) .This has the effect of modifying and impose different forms of profiles along the blade. The profile shape at a given point of the blade radius is defined by the chord width. Héliciel searches its database, the profiles corresponding to better the conditions of width and thickness required by the user.The database is not infinite, the forms found by heliciel will therefore, can be of different thickness than required.

- orange: the required thickness with sliders

- green: the thickness found in the database

When you click on re build the propeller, Heliciel search the database for matching profiles to the required thickness and selects the profileswhose performances of lift / drag ratio are the highest. the incidence angle providing the best lift / drag ratio being selected for each blade profiles, Data Cd and CL are used are used to solve the system of equations of the induced velocities, by the method of blade elements and the change of momentum(BEM), taking into account the correction of the blade tip losses resulting from the vortex theory. When the induced velocities are resolved Heliciel calculating the performance, torque and thrusts on each blade elements, and derives the overall result for the propeller.Twisting of the blade is made so that the angles of incidence reflect induction.

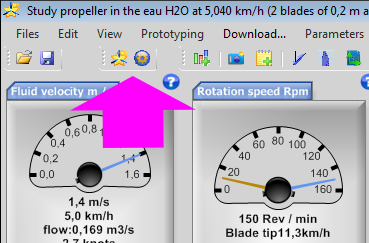

In reality it is quite possible that the fluid velocity or the speed of rotation is different from the operating point for which the propeller or turbine was drawn.For example, at the beginning of the rotation of a wind turbine blade, it is interesting to know the couple at a given wind speed at a rate of almost zero rotation,to know if the drive efforts of the various equipment are not higherand therefore prohibits the start of our propeller ....Or for a boat propeller, which the speed differs from the cruising speed, at which the propeller was twisted. Twisting (design) of the blade was reviewed for a given rotational speed, calculating offdesign performances can calculate the performance of the propeller after a change of the operating point,that is to say a change in the rotational speed or velocity of the fluid. At each change of the operating point you will see activate the calculate button "off design"

In this example the speed of a wind turbinewhose twist is optimized for 800 rpm, was set to zero to simulate the start of the wind turbine. A simple click and the starting torque of your wind turbine displayed:

Another method of construction is possible to make an estimate of the performance of an existing propeller raising his pitch to different radius. This method of retro design is detailed on page "Performance and modeling of an existing propeller"

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies