Understand and master the design of Wind turbine and propellers blade:

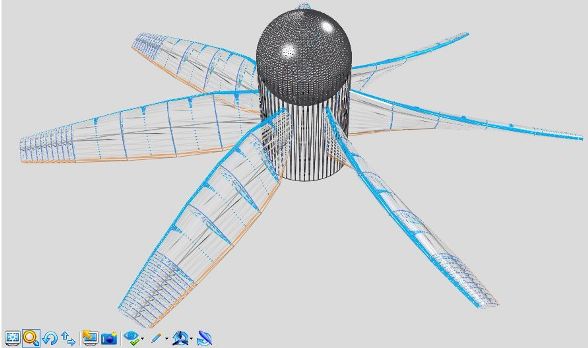

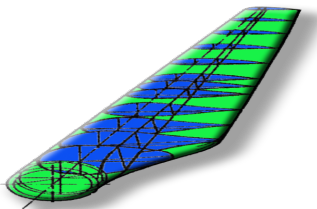

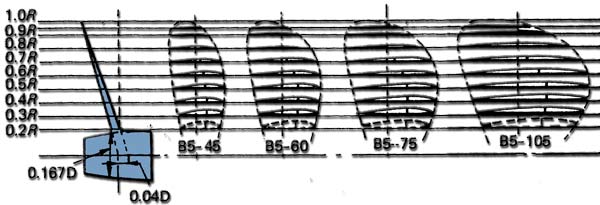

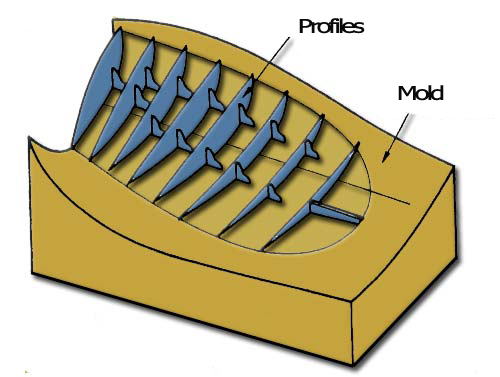

Propeller or a wind turbine comprises essentially a hub and blades. The blade of the propeller or the wind turbine blade can be considered as a rotating wing. The blade shape is defined by profiles, chosen for their aerodynamic performance. Profiles are distributed along the blade of the wind turbine or the propeller, in order to achieve the best compromise between resistance and production of lift.

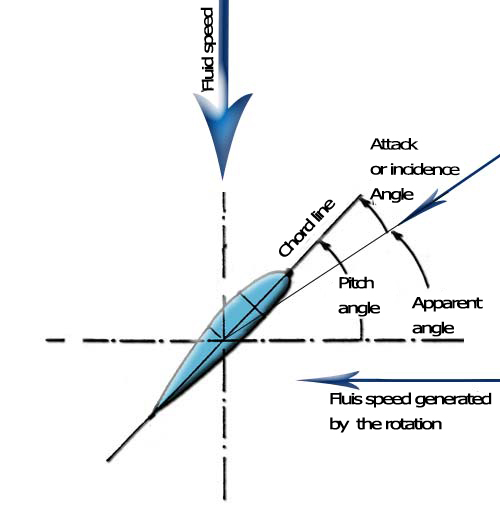

The rotation of the propeller generates a speed and an apparent angle, which vary depending on the position of the observed point on the radius of the blade. To keep an optimum angle of incidence, the profiles of the blade of the wind turbine or the propeller, will have a pitch adjusted to apparent velocities along the blade. Pitch profiles varies and causes a twist of the blade.twisting of the blade of the propeller or turbine blade, is the angle measured between the chord of the profile at the blade root, and the profile chord at the blade tip.

The variation of the pitch is to rotate the blade of the wind turbine or the propeller on its axis so as to correct the loss of performance.The pitch variation also helps regulate the speed of the wind turbines.The number of blade of the wind turbine or the propeller varies according to the torque and velocity at operating point .A wind pump will not have same number of blade, than wind turbine of electricity generation. A sailing boat propeller has a blade shape different from a speedboat propeller.

the matter and the structure of the blade, are taken into account in the calculation of resistance of the propeller or the wing by Heliciel software.A quick tour of the horizon on the technical materials and construction of the blades will be useful.

- Blade propeller plane

Of course, we tried to replace the duralumin with a lighter metal : Magnesium alloy. The lightness of the blade is an extremely significant element because the centrifugal forces - tens of tons - are proportional to the density of the material used.The reduction of weight of the blade saves us on all fronts: reducing of: sections, weight, size of the parts of the hub.However forging blades magnesium requires a more powerful tool, as forging blades duralumin. On the other hand, a solution has been provided by the development of matrixing for the manufacture of the blades. Another material used for the propeller blades: the steel. Steel is used for large propellers, which is hollow,then it is made of two half shells pressed, sealed over their periphery and having internal stiffeners;the durability of the welds naturally asked a long development,sheets "rolling" on each other for the first achievements.

Carbon is increasingly used and seems to impose. The performance of lightness and strength make it material of the future. A perfect mastery of the molding is however need, to a good balance and absence of defects.

- Blade propeller boats

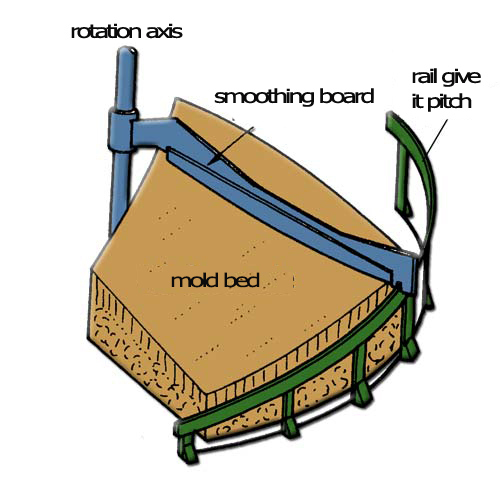

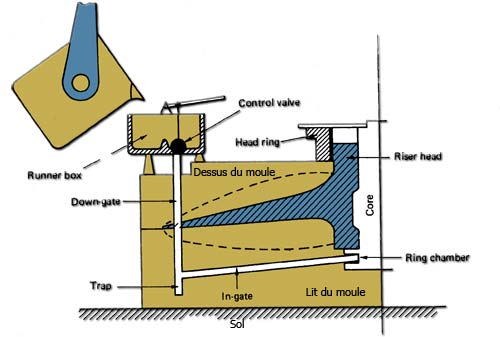

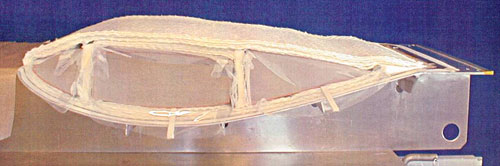

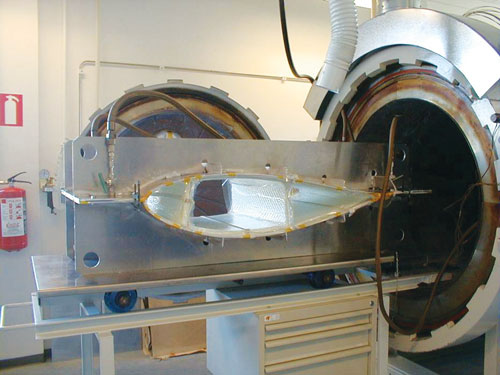

the propeller blades of boats are generally molded: a mold bed is constructed, and the smoothed out to pitch propeller using a rotating plate around a sliding and guided by a rail axis giving it propeller pitch:

A new generation of propeller is created with carbon entering and winning in the market for boat propeller::

- wind turbine blade

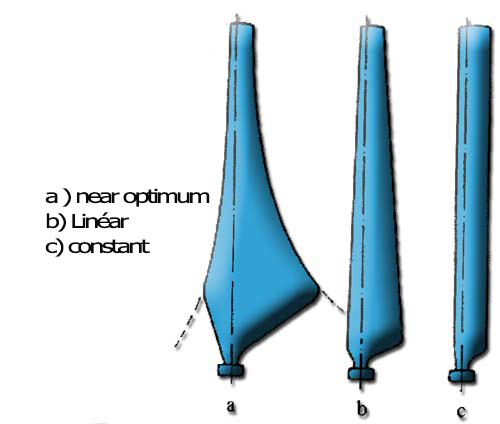

A construction technique used for small wind turbines is sometimes pultruded fiberglass. The pultruded blades pass through a shape that gives them their profile, but the distribution of chord is necessarily constant.Molded blade thus help create more efficient aerodynamic shape, than the pultruded blade.

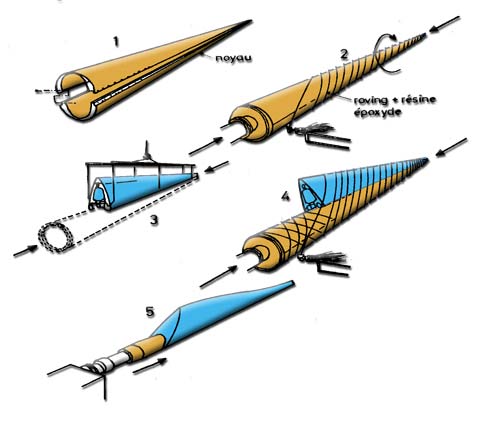

another method to construct fiber and resin, is to wrap a wire coating resin around the blade by turning on a lathe::

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies