Understand and master Wind turbine propeller for energy harvesting:

See also :

The wind turbine rotor is a propeller for energy harvesting.The components of the wind turbine allow the transformation of wind energy. We have defined the notion of performance and limits, in the article on propellers capture energy.

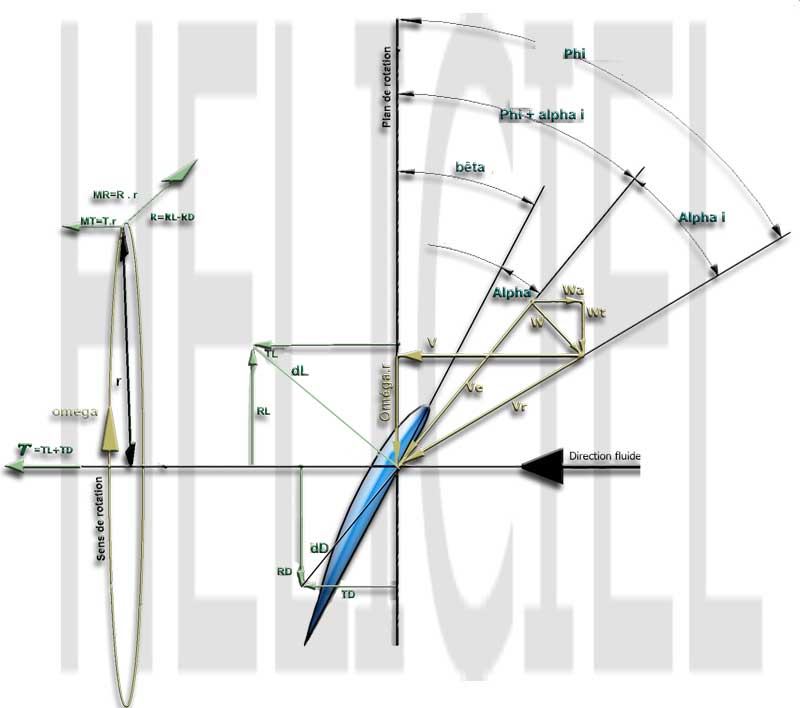

The geometric definition of a wind turbine starts by choosing the diameter depending on the wind on the site and power, we want to produce. Knowing the average wind speed, we estimate the diameter of the wind turbine needed to produce the desired energy.(see propellers capture energy and wind energy).To build a wind turbine and choose the shape and number of blades of the wind turbine, it is necessary to establish what will be its operating point. . The operating point of the wind turbine is defined as the wind speed (we can't change it) and the speed of rotation of the rotor. Select the operating point of our wind turbine is set the optimum rotation speed of our wind turbine. We will see the parameters determining the rotation speed that characterizes the wind turbine. The dedicated to optimizing the rotation speed page will be available for further study.

Of the operating point resulting the twisti of our wind turbine blades. A fixed pitch propeller is twisted for an operating point, a variable pitch propeller is also twisted for a single operating point. The variable pitch does not change the twist and is often used for an adaptation of the pitch or speed control, but the twist of the blade is designed for a single operating point where the wind turbine is at its best efficiency. The twist can not be changed once a blade constructed.This implies that we will have a wind turbine rotation speed adjusted to a nominal wind speed at which it has maximum performance.It is important to choose the wind speed by analyzing meteorological and statistical data of the location.

- Statistics winds should be observed in terms of power and not speed! 2 hours winds at 10 km / h does not give the same power that one hour wind 20 km / h because power grows with the cube of the velocity! (see nominal wind speed)

Choice of speed of rotation of a wind turbine:

For a wind turbine of small size, the centrifugal force at the blade tip, allow rotational speeds quite important to directly drive a generator, but the largest wind turbines are equipped with a multiplier for maintaining a reasonable velocity of rotation. Some large wind turbines have, generators slow without multipliers, and some small wind turbines have a multiplier... There are endless combinations "speeds / multiplier / generator" and choices are usually governed by manufacturing costs copper in generator) and maintenance (high speed rotation = rapid wear)

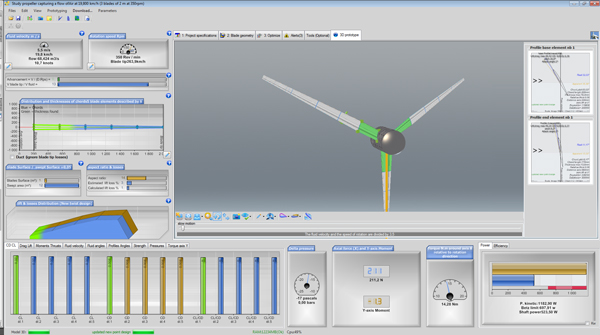

Study of a three-bladed wind turbine with héliciel:

The operating point is related to a manufacturing strategy. Depending on your choice of rotation speed so you decide to an operating point.The notion of performance and speed is also to assess. The power of the propeller is: Power=torque (Nm) on the shaft X rotation speed (Rad/sec). Torque is the force applied on the blades by the wind

- When the speed is low, the apparent wind and the angles of incidence of profiles section generate a better alignment of lift and drag forces , with the plane of rotation

- But when it slows down, the apparent gap between the blades increases, if we do not want to lose the energy of the air passing between the blades, we must add blades,but not too much because they might disturb each other.There is therefore an ideal rotation speed for each number of blades..

- For an optimal "Efficiency / manufacturing cost" ratio , a minimum number of blade is desired.

- But to use all the air with a low number of blades, we must rotate faster so that "apparent space" between the blades is reduced to its ideal size.

- When the speed is fast, the apparent wind and the angles of incidence of profiles section generate a bad alignment of lift and drag forces , with the plane of rotation...

Disadvantages of these high speeds are balanced by the fact that the profiles produce better performance at high speeds, for the same power, high speed generates less torque reaction, therefore less rotation of the flow, so less losses ......

- High specific speeds

benefits disadvantages Captures the energy with a low blade number, thus providing the benefits of the low number of blades: economic cost in manufacturing the apparent wind and the angles of incidence of profiles section generate a bad alignment of lift and drag forces , with the plane of rotation, This requires good profiles quality sometimes difficult to achieve. Rotating tangential flow downstream of the propeller Revelle energy lost by the system. At equal power (Pw = torque nm x speed rad rotation / sec), a high rotational speed uses less torque generated so less losses. sometimes requires assistance of starting when the starting torque is insufficient speed of rotation closer to generator system (the price of the generator and gear box will be lower) speed of rotation and torque not suitable for pumping limited exposure to violent winds

- low specific speed

This list is far from complete because each turbine is the result of a compromise argued by the constraints of the project . In this tutorial we opted for a small number of blades to generate electricity. We take three blades. The specific speed (blade tip speed / wind speed) for optimal 3-blade wind turbines is generally 7.

benefits disadvantages Allows the use of simple forms blades economic cost in manufacturing to get a good performance it takes a lot of blades (more expensive, heavier, to the wind when storms ...) start even at low wind speeds Rotating tangential flow downstream of the propeller Revelle energy lost by the system. At equal power (Pw = torque nm x speed rad rotation / sec), a low rotational speed uses more torque generated so more losses. speed of rotation and torque suited for pumping speed of rotation far to generator system (the price of the generator and gear box will be higher)

If you wish to make a machine run at low speed with little wind (wind pumps) it is preferable to start with very little wind, so we put a lot of blades.

.

If you wish to sell electricity produced with a minimum of material (the manufacturing cost of the blades is a profitability factor) we seek the minimum of blades.

Why bladed propellers are not many more? It is purely mechanical, the imbalance around the axis of rotation and the alternation of wind forces around the pivot of the propeller generates vibrations and destructive effects, that we must balance.Some manufacturers nevertheless exploring this way:

The two-bladed propeller also has problems balancing and vibration related to the fact that the rotational inertia is maximum when the blades are horizontal, and becomes zero when the blades are vertical.

The three-blade propellers offer stability that manufacturers seem to have preferred.

The optimization of a project must take into account the parameters of efficiency but also cost of manufacturing, durability, noise, aesthetics, ease of manufacture. To deepen the understanding of wind turbine blade: A tutorial design wind turbine blades:

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies