How to edit propellers and wings performances curves with heliciel 3D simulation software:

Exemple of propeller blades and wings thrust and efficiency performances curves edition :

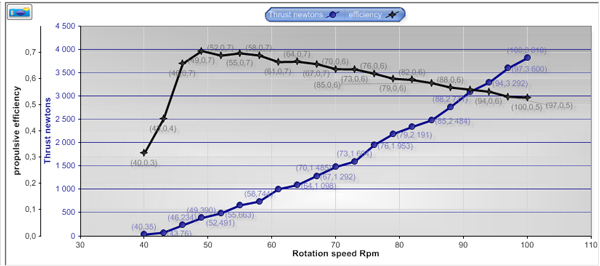

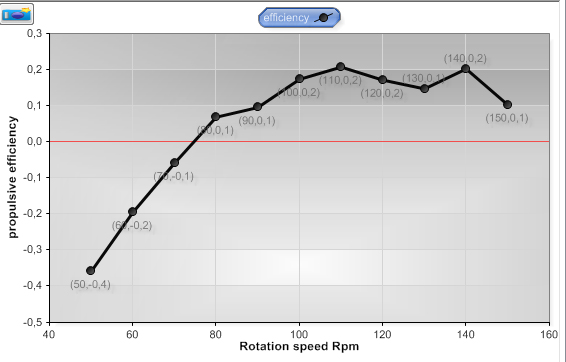

A series of graph showing the propeller or wing performances, at versus rotation speeds(for propellers), or fluid speed(for wings), allow to analyse the strengths, powers or efficiency of the system:

- The multiple analysis:

Or under the tab 3:Optimize, use the "multiple analysis" button

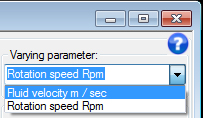

- Determine the varying parameter: The operating points are determined by the fluid velocity and speed of rotation,varying parameters of the analysis are: the rotational speed, and the fluid velocity:

Selection parameter varying

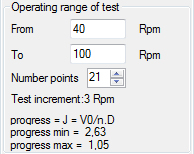

- Determine the range of test: The varying parameter is tested within the allowable range. The test range is divided into the choosen number of test points.

- You can select two types of analysis :

- "Refreshing twist":If you want the optimum twist is rebuilt at each operating point tested, héliciel updates twisting, and calculates the performance of the propeller at each test point. You can then test the optimum performance that offers your propeller blades with the given dimensions.

- "Off design/Reverse Egineering":Twisting and rigging of the propeller will be constant and the propeller will be analyzed in "offdesign" way. So you see the evolution of performance of a given propeller outside of its design point.

It remains only to start the analysis.Graphs can be saved, a "compare" graphic used to display the selected curves, data calculations can be recorded as text or spreadsheet ...

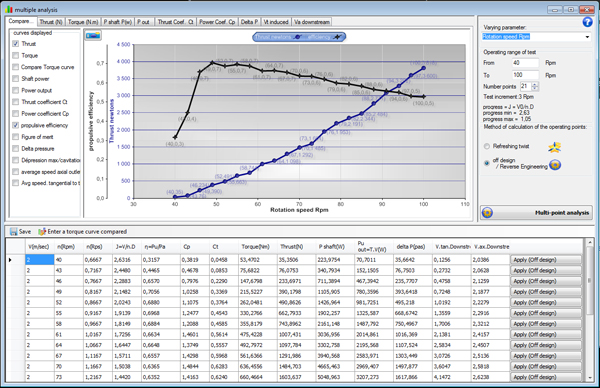

Ranges selected test can give results that completely out of the mode of operation of the propeller and give such negative returns: below for example, the rotation speed range tested for this thrust propeller, tells us that in the fluid velocity of operating point of design (2 m / s) ,our propeller has a propulsive efficiency of 0.2 at 140 rpm,But at 60 rpm performance is negative, our propeller operates in energy harvesting ...

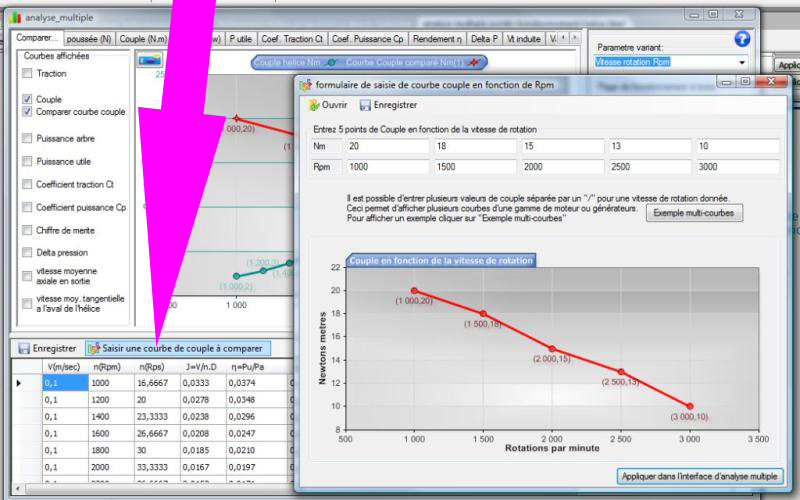

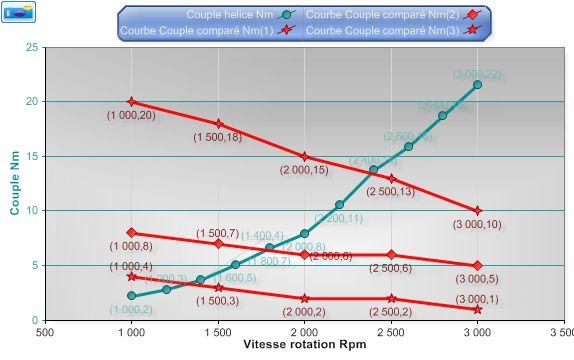

- Electric motors have a rotational speed changed by the resisting torque applied to them. The actual operating speed of an engine of this type, corresponding to the speed given by the intersection between the torque curve and the curve of load torque of the propeller.

- For a wind generator or tidal turbine type powered by a propeller energy recovery ,the problem is the same, operating speed is the point of intersection between the curve of the generator load torque and the torque curve of the propeller.

To quickly see what will be the operating speed of your system: generator / turbine or motor / propeller, Simply place on a same graph, the torque curve of the propeller, and the torque curve given for the motor or generator.To facilitate graphics resolution, of the actual operating point of the system, it is possible to insert your torque curve (provided by the manufacturer of the generator or motor) and make it appear superimposed:

input torque curve:

- the propeller mounted on the engine whose torque is described by curve 1 operate at 1300 rpm

- the propeller mounted on the engine whose torque is described by curve 1 operate at 1750 rpm

- the propeller mounted on the engine whose torque is described by curve 1 operate at 2400 rpm

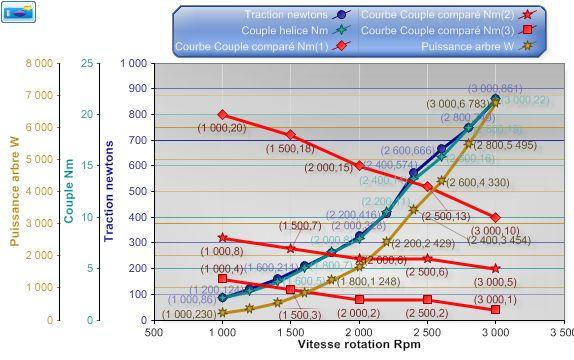

ISo here we find that:

- the propeller mounted on the engine, whose torque is described by the curve 1, will provide a thrust of 150 newton at 1300 rpm and a shaft power of about 300 watts

- the propeller mounted on the engine, whose torque is described by the curve 2, will provide a thrust of 250 newton at 1750 rpm and a shaft power of about 1200 watts

- the propeller mounted on the engine, whose torque is described by the curve 3, will provide a thrust of 550 newton at 2400 rpm and a shaft power of about 3400 watts

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies