see also: evolution propeller design methods

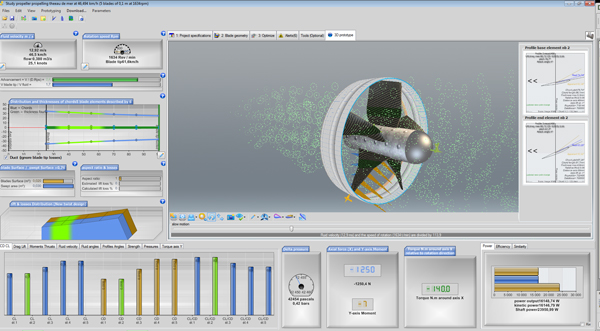

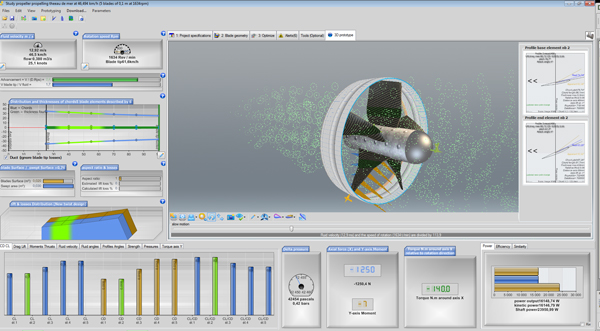

Design: propeller turbine, screw, aerial, marine, turbine, tidal, wind, kaplan, foil, wings, 3D. Discover heliciel software: Modeling aerial propeller in heliciel Boat propeller modeling in heliciel Ventilation propeller modeling in heliciel Wind turbine propeller modeling in heliciel Tidal turbine modeling in heliciel Kaplan turbine modeling in helicielaxial propeller pumps, waterjet pump jet

Know the axial propeller pumps and waterjet pump jet:

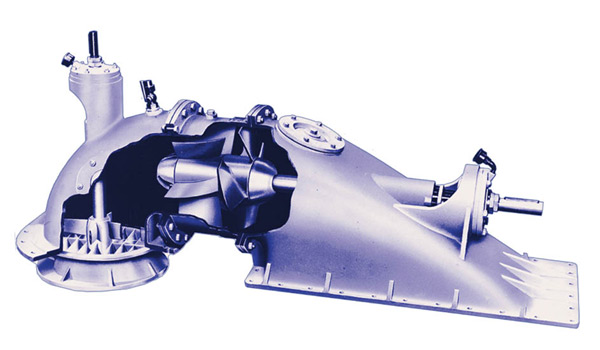

The axial pumps, propeller pump jet, are pumps designed to generate a high flow rate and low pressure variation. They are mainly used in irrigation or hight speed boats(waterjet).

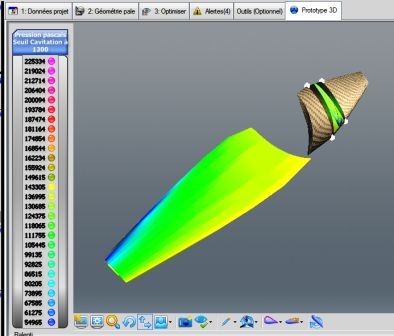

The propeller axial pump is comparable to the boat ducted propeller. the operating point of the propeller pump will be determined by the desired flow rate. This is not the thrust will be sought but the pressure variation.The propeller will be performed to ensure that at the desired rate, it generates the pressure difference equal to the head loss of the duct where the fluid flows.

Jet pumps used as thruster for submarines, jet ski or adapted on outboards are from this category. The diameter of the propeller is sometimes limited by the "draft boat" or by limiting the speed of the blade tip speed (cavitation).When you want to make a strong push with a small propeller there is the problem of pressure leakage at the tip of the blade but also the blade roots..

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies