construction of a wind turbine permanent magnet axial flux generator

Understand how the wind turbine permanent magnet axial flux generator works:

See also: wind turbine generator

This article is excerpted from the book "The Eolian mini" (Emmanuel Riolet to Eyrolles edition). It covers construction of a permanent magnet axial flux generator. it is enhanced images of a self-build a generator of a wind turbine axial flux permanent magnet "Steven Fahey" whose full text is here

It is a established fact, to produce maximum power, you need a magnetic field the strongest possible. That is why we will use neodymium magnets, which are also called "permanent magnets" because of their long life. It is composed of a neodymium-iron-boron and are at least ten times more powerful than conventional magnets.It keeps intact all their magnetic property for at least three centuries.

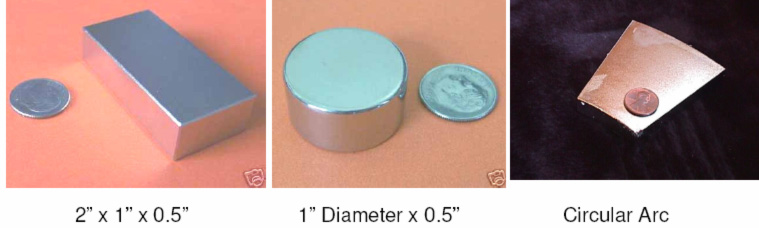

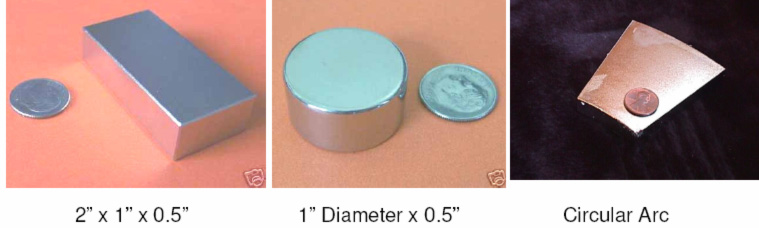

To purchase, the easiest is to log onto the Internet and type in the keywords "magnets - neodymium" in your favorite search engine. Manufacturers and retailers indicate the strength of their magnets either Gaussian or in pounds traction. Do not be fooled by the first merchant came, compare and order what is more powerful for the same density. You can see that there are magnets of almost all forms.

In the interests of simplicity and maximum efficiency, we will opt for a rectangular

Warning: handling magnets

You just got your magnets. Before you rush to your package, some advice is needed on handling. Magnetism is a great enemy of electronics. So be careful not to approach too close to your magnets all that is likely to be affected by the field. Take care to remove at least 30 cm sensitive objects, such as your watch, cell phone, credit card. . .Make also very careful when you handle your magnets. They are so powerful that they can quickly cause you mishaps. The first risk is to pinch your fingers strong and the second is to break your magnets. As the neodymium are powerful, as they are fragile. If they ever find themselves glued to each other, the right way to separate is to drag and not to seek to clinch.

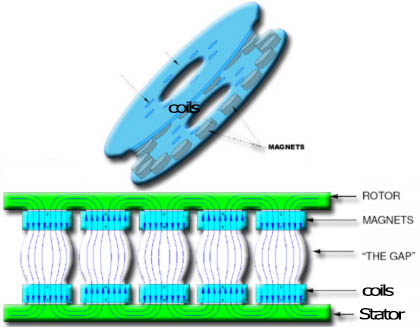

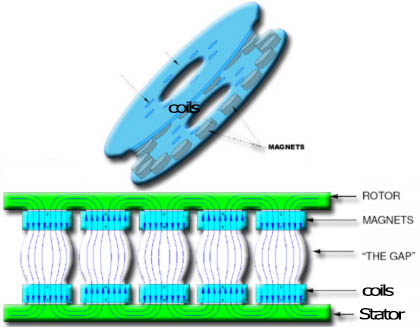

As you can see from the diagram above, this generator is a very simple design. you can see the rotor on which are fixed magnets, the stator on which the coils are fixed.a housing holds the assembly, ball bearings optimize rotation. In the end, it is composed of a casing of stainless steel or resin and fiber, a neodymium magnet rotor of enamelled copper wire and two ball bearings. The rotor must be made from a material that is both lightweight and very strong, such as wood coated with resin, fiber and resin, aluminum. . .

Regarding ball bearings, do not skimp on quality. They must be robust to withstand heavy work and able to withstand the stresses of climate

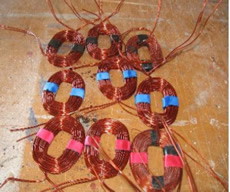

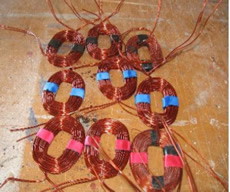

One of the many advantages of this type of generator is that you can make custom size as the performance.To design one that works flawlessly, it must first perform a clever calculation that includes magnets size and strength in gauss; this will determine the section of copper wire coils and the number of turns. Each case is different, the easiest way is to start with plans that you can easily find on the Internet with the keywords adequate. You can also start randomly adjust your coils up to get the desired result. Pour tester le rendement pas la peine de faire plusieurs bobines Une seule suffit,To test performance, no need to make several coils, One simply must be put in place on the stator and rotating the rotor to measure current. It only remains to multiply the voltage by the number of coils for the overall result, and modify the coil to the desired result.

When it's good, you can go into the making of other coils on the same model. What You Should Know schematic is that the longer you have your coils turns on, the more they produce, the more the wire is narrow, the more you tend to get the voltage, and the section will be larger, the more you will tend to get amperage. From these data, it's all about dosage. Ideally, you should get a voltage of 13 volts with a good amp to 600 revolutions per minute..

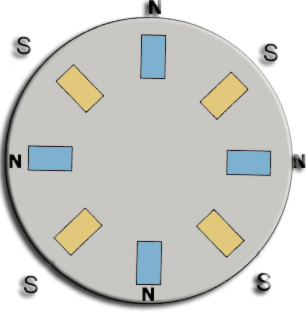

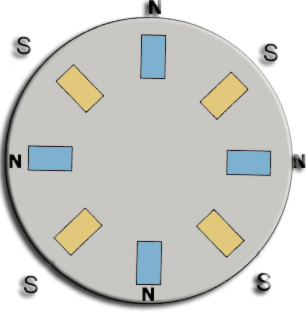

Arrange your magnets, by reversing their polarity, to obtain the alternating current. To check the polarity, you need a compass that will tell you the south and north side

Regarding the coils, they should be made with care. The coils should be as regular as possible. If this is a problem, you can always try to get all the coils made on electric motors. It will work well if they are exactly the same type and, of course, they are not damaged.Otherwise, you can always go to a professional.For a simple task like this, it should not cost you too much. When fixed to the stator, the coils must be connected in series. To connect, you must first scrape the thin insulating layer of copper wire on a centimeter, with a knife, so that the end of the wire can make contact with each other. For safety, it is advisable to strengthen and protect the connections with heat shrink tubing. The faces of the magnets will brush against closer to the coils in order to have a magnetic field, the most effective. This requires a perfect fit rotor. To properly stabilize the coils, drown them in resin:

you must also install a diode bridge, suitable for the power generator next to the regulator to rectify current. If you are not good at all in electronics, you can find ready-to-use in all stores components. It's really cheap. You just have to connect son following the indications of the case.

Summary This type of generator is ideal for wind energy. Its strengths are very numerous:

- It produces a load current at low revs.

- It has a good overall performance.

- Its size is adjusted according to your project.

- It is economical compared to buying a new generator.

- It is simple in design, so easy to maintain.

- It is very robust if it is designed with good materials.

- It requires no excitement, so no friction to slow the rotor and no coals to replace.

we must think now make a driving mechanism. This is what we will do with the next chapter is devoted to the

design of the blades of wind turbines

Global site map

Global site map Mecaflux

Mecaflux Tutorials Mecaflux Pro3D

Tutorials Mecaflux Pro3D Tutorials Heliciel

Tutorials Heliciel Mecaflux Store

Mecaflux Store Compare software functions

Compare software functions Quotes, Orders, Payment Methods

Quotes, Orders, Payment Methods project technical studies

project technical studies